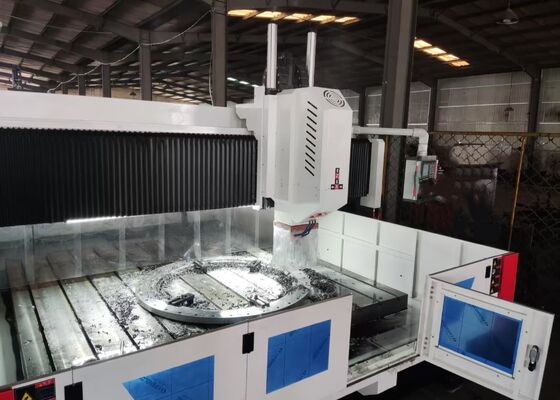

1000mm Gantry Height Dual Head CNC Plate Milling TappingMachine And Workpiece Size 3500x3500mm

Product Introduction:

This equipment is engineered for drilling, chamfering, tapping, and milling of plate and structural components. It is primarily employed for high-efficiency drilling tasks on workpieces such as flanges, discs, rings, and plates, within the specified thickness range for effective processing. It is capable of drilling both through and blind holes on single-material and composite materials. The machining operations are digitally controlled, ensuring ease of operation. The system enables automation, delivers precise outcomes, and is well-suited for processing a wide range of products while supporting large-scale production.

Specifications:

| Workpiece size |

LxW |

3500x3500 mm |

| Gantry height |

1000mm |

| Workbench |

T-slot width |

28mm |

| Four Jaw Chuck |

1 set |

| Drilling power head |

Qty. |

2 |

| Spindle taper |

BT50-190 |

| Max.drilling diamter |

Φ100 mm

(Carbide core bit)

|

| Φ80 mm (U drill) |

| Max.thickness |

≤300 mm |

| Max.tapping diameter |

M30 mm |

| Spindle speed |

30~3000 r/min |

| Servo spindle motor power |

2x37kW |

| Distance from the lower end of the spindle to the worktable |

200-1000mm |

|

Lateral movement of power head

(X1 axis)

|

Max.horizontal stroke |

3500 mm |

| Lateral movement speed |

0~8 m/min |

| Servo motor power for lateral movement/torque |

4.2kW |

|

Lateral movement of power head

(X2 axis)

|

Max.horizontal stroke |

3500 mm |

| Lateral movement speed |

0~8 m/min |

| Servo motor power for lateral movement/torque |

4.2kW |

| Gantry longitudinal movement (Y axis) |

Max. feed stroke |

3500 mm |

| Feed moving speed |

0~8 m/min |

| Feed servo motor power/torque |

2x4.2 kW |

| Vertical ram feed motion (Z axis) |

Max. stroke |

800 mm |

| Moving speed |

0~6 m/min |

| Servo motor power/torque |

4.2kW |

| Three-axis positioning accuracy |

X/Y |

≤0.05mm/1000mm |

| Three-axis repeat positioning accuracy |

X/Y |

≤0.03mm/1000mm |

| Pneumatic system |

Compressed air supply pressure |

≥0.6MPa |

| Chip conveyor and cooling |

Number of chip conveyors |

2 |

| Chip removal speed |

1m/min |

| Chip conveyor motor power |

2X0.75kW |

| Cooling method |

Internal cooling + external cooling |

| Automatic lubrication system |

Lubrication pressure |

2MPa |

| Lubrication point oil filling amount |

0.1mL |

| Lubrication cycle |

6-10min |

|

Electrical System

|

CNC system |

GSK218MC

(display 10.4 inch)

|

| Number of CNC axes |

4 |

| Total power |

/ |

About 100kW |

| Overall size |

LxWxH |

6500x6800x3000 mm |

Equipment Structure:

The machine base is constructed from cast material and incorporates key components including the worktable, movable gantry, movable sliding saddle, drilling and milling power head, automatic lubrication system, protective enclosure, circulating cooling system, digital control unit, electrical system, and other essential elements. It is fitted with rolling hard rail pairs for reliable support and guidance, along with precision lead screw pairs for driving motion. The machine is distinguished by its exceptional positioning accuracy and high repeatability in positioning.

Product Features

1. Power-off Memory Function:

In the event of a sudden power failure or other interruptions, this function allows for the rapid and easy retrieval of the last drilled hole position prior to the power loss. This enables operators to quickly resume work, minimizing time spent searching for the previous position and enhancing operational efficiency.

2. Photoelectric Edge Finder:

The equipment is equipped with a photoelectric edge finder, enabling easy and precise location of the workpiece position.

1). Insert the edge finder into the spindle chuck of the machine, and slowly rotate the spindle to adjust its concentricity.

2). Use the hand wheel to move the main spindle so that the edge of the edge finder’s steel ball gently contacts the workpiece. Once the red light stops, the spindle can be reversed. Move the spindle back and forth to identify the optimal point where the steel ball of the edge finder touches the workpiece.

3). Record the X and Y axis values displayed by the CNC system at this position and input them into the computer.

4). Repeat the process to find multiple detection points.

3. Laser Interferometer:

Each machine is calibrated using an American API laser interferometer, which precisely checks and compensates for pitch errors, backlash, positioning accuracy, and repeatability. This ensures both the dynamic and static stability, as well as the machining precision of the equipment. The system is designed to guarantee the 3D machining accuracy and circularity of the machine.

.

.

This sophisticated CNC gantry system is specifically designed for high-efficiency drilling and marking of plate and sheet metal components. It has been carefully engineered to deliver precise processing of plate-like workpieces and structural assemblies, making it particularly ideal for machining flanges, discs, ring-shaped parts, flat plates, and similar components. A critical operational condition is that the thickness of the workpieces must be within the machine’s specified effective machining range.

In steel structure fabrication facilities, this equipment performs precise drilling and milling operations on structural plates and connection components, providing a solid foundation for the reliable assembly of steel frameworks. In the wind energy industry, it offers advanced, high-precision machining capabilities for wind turbine towers and flanges, ensuring these components are engineered to withstand extreme environmental conditions, such as high winds and temperature fluctuations. For bridge construction, the equipment processes bridge girders and support brackets, enabling the creation of durable, stable connections capable of withstanding dynamic loads throughout the bridge's extended service life.

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!  ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!